Microstructure test

Microstructural testing allows the detailed study of the structure of materials. By analyzing the microstructure, important information about the properties, quality and performance of a material can be obtained.

Application areas

It is mainly used in industries where the study of the structure of materials is important:

Here particularly relevant to evaluate the properties and quality of metals such as steel, aluminum, copper and their alloys. This includes the investigation of microstructural phases, grain size, grain orientation and impurities.

In the automotive industry, microstructural testing plays an important role in evaluating the material properties of engine components, transmissions, chassis parts and other components. It allows the evaluation of strength, toughness, wear resistance and other important properties.

In the aerospace industry, microstructural testing is used to check the material properties of aircraft structures, engine components, turbine blades and other critical parts.

In the power industry, microstructural testing is critical to verify the quality and reliability of components such as turbine blades, piping, and pressure vessels.

Microstructural testing plays a crucial role in various industries such as metal processing, automotive, aerospace and electronics. It enables materials characterization, quality assessment, process optimization, materials selection and contributes to research and development of new materials. Overall, microstructural testing provides valuable insight into the structure of materials and its effects on their properties and performance.

The most important areas of application of microstructure testing include:

Microstructural testing is used during the manufacturing process of materials to ensure that the desired properties and quality standards are achieved.

To ensure compliance with required specifications, for example, the correct heat treatment is monitored during incoming goods inspection.

In the event of material failure or damage, microstructural testing is used to determine the causes and identify possible sources of failure. Examination of the microstructure helps to identify strength reductions, microcracks, corrosion or other defects and to understand their effects on material behavior.

Microstructural testing also plays a central role in materials research and the development of new materials. By studying the microstructure, relationships between the microscopic structure and material properties can be explored to develop new materials with improved properties.

The application areas of microstructure testing are diverse and range from quality assurance in material production to failure analysis and material development. It is an indispensable tool for comprehensively evaluating and optimizing the properties and performance of materials.

Our products for microstructure testing applications

QutEC.sbc

- Microstructure testing of hardened sprockets and gearsand gears

- Automated feeding of the test parts

- Real-time display of defective Test parts

- automatic IO/NIO evaluation

- Testing speed: 25 parts / minute

- free creation of calibration curves

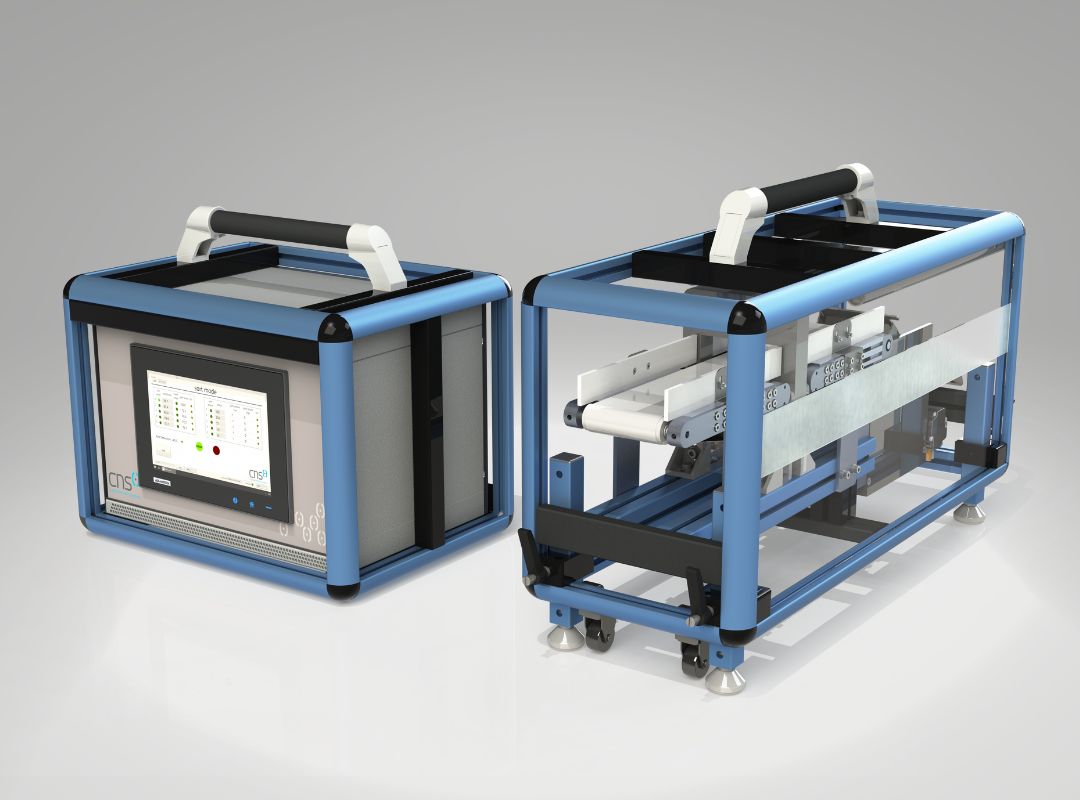

QutEC.sort

- No damage to the components

- Reliable testing of coated or jacketed parts

- Setup wizards for easy operation

- manual or automated component feeding

- Inspection speed up to 1 part / second

QutEC.sort.light

For support during product launch, process changeover or in the event of a complaint.

Optimal for service providers with changing locations.

Simple, mobile and fits in almost any trunk!

The system can be used variably in production lines or as an external test station.